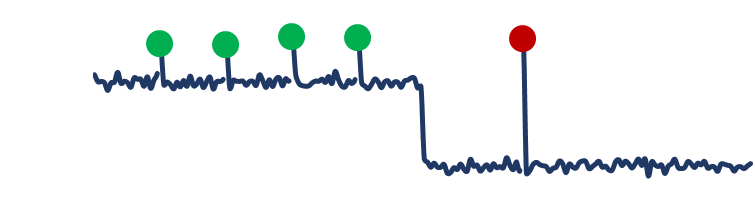

Makine öğrenmesi algoritmaları ile otomatik anomali tespiti yapılır

Makine öğrenmesi algoritmaları ile otomatik anomali tespiti yapılır  Karmaşık veri işlenerek bakım ekiplerine erken ve isabetli bildirimler sağlanır

Karmaşık veri işlenerek bakım ekiplerine erken ve isabetli bildirimler sağlanırKritik Üretim Ekipmanlarının Durum Takibi İçin Bütüncül Platform Çözümü

İhtiyaç Analiz Servislerimiz ile Doğru İlk Adımı Atın

Daha Düşük Karbon Salınımı İçin Kalite Kayıplarının Önüne Geçin

Kimya

Petrokimya, sabun, gübre, ilaç, boya ve sentetik elyaf gibi pek çok sektöre ara ürün ve hammadde temin eden kimya endüstrisi, hızlı ve sürekli üretimin yaygın olduğu tesislerdir. Kompresör, pompa ve proses özel makinelerinin bulunduğu bu tesislerde plansız duruşlar üretim kapasitesini etkiler. Sürekli üretim dolayısıyla personelin ölçüm imkanları kısıtlıdır. Pdmechanics kimya sektöründe üretimde görevli makineler için verimli bir kestirimci bakımı mümkün kılıyor.

İmalat

Sürekli üretim yapan imalat sektöründe üretim makinelerinde gelişen arızaların erken aşamada tespiti kritik önemde. Üretimde görevli makinelerde gelişen arızalar plansız duruş öncesi üretim kalitesini de etkileyip kaynak israfına yol açıyor. Pdmechanics farklı makine tiplerinin ve değişken üretim koşullarının bulunduğu imalat sektöründe isabetli risk skorlamaları ile üretim güvenilirliğini artıran bir çözüm sunar.

Metal

Pompalar, fanlar, motorlar ve dişli kutuları metal endüstrisindeki ortak kritik varlıklardır. Döner yataklı elektrik ark ocakları, üretim vinçleri ya da sektöre özel ekipmanlardan oluşmuş üretim hatları düzenli durum izleme ve veri analizi gerektirir. Üretim için kritik bir ekipmanın arızası bütün üretimi durdurabilir. Pdmechanics kablosuz sensör çözümlerini de kullanarak tesis içinde erişimi zor bölgelerden veri toplayıp anomali tespitlerinde bulunur, üretim verimliliğine katkı sunar.

Gıda

Yüksek işletme maliyetleri ve plansız duruşların finansal riskleri gıda sektörünü operasyonel güvenilirliği artırmanın yollarını aramaya itiyor. Fan, pompa ve kompresörlerden oluşan ünitelerin sağlıklı çalışması tüketiciyi direkt etkileyen ürün kalitesi için bir zorunluluk. Pdmechanics ileri veri analitiği çözümü ile üretim hattındaki ekipmanların ve soğuk hava depolarının güvenilirliğini artırır, erken teşhisleri ile bakım ekiplerinin aksiyonuna olanak tanır.

Otomotiv

Artan rekabet ortamında, otomotiv endüstrisi operasyonel verimliliği artırmanın ve bakım maliyetlerini azaltmanın yollarını arıyor. Pazar araştırmaları plansız duruş kaynaklı üretim kayıplarında otomotiv endüstrisinin en çok maddi zarar gören sektörlerden biri olduğunu gösteriyor. Pdmechanics, farklı tip verileri işleyerek üretim hattındaki ya da test istasyonlarındaki anomalileri tespit eder, gelişmekte olan arızaları günler öncesinden bakım ekiplerine bildirir.

Endüstri 4.0'ın Önemi

Kablosuz Titreşim Sensörü Seçenekleri Arasında Kararsız mısınız ? Doğru Seçimi Yapabilmek için Bu Temel Unsurları Dikkate Alın

Vaka Analizi - ID Fan Online Durum İzleme ve Arıza Teşhisi

Vaka Analizi - Erken Safhadaki Elektrik Motoru Rulman Arızasının Zarf Analizi ile Tespiti

Başarılı Bir Online Durum İzleme Projesi için Dikkat Edilmesi Gereken Dokuz Önemli Nokta

Pdmechanics Çözümü ile Artan Tesis Güvenilirliği

Vibrasyon Analizi

Dijital Fabrika

Kestirimci Bakım